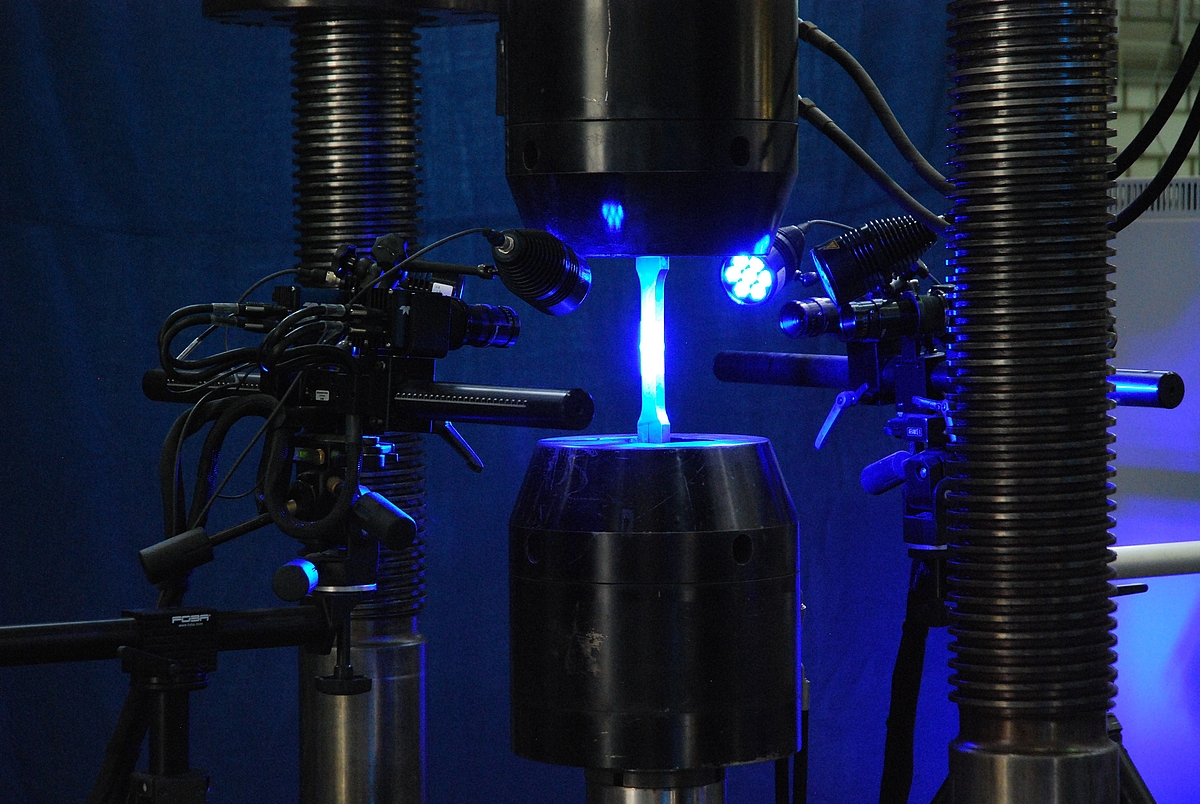

Loading devices, testing machines

- Servo-hydraulic single test cylinder with hydraulic clamping devices as well as measuring, control and evaluation system (MTS Systems) for static and dynamic tests in the load range up to 1.2 MN for compression and tensile tests.

- 2 servo-hydraulic single test cylinders DAS 40 (MFL) for static and dynamic tests in the load range up to 400 kN for compression/tensile tests

- Universal testing machine HUS 60 (MFL) for static and dynamic tests in the load range up to 500 kN for compression/tensile tests

- Resonance test frame (FRAME WORK) for dynamic compression/tension tests up to 560 MPa and test frequencies up to 250 Hz

- 8 x 16 m clamping field with anchors (MFL)

- Load frame in modular design for multi-axis testing of specimens with different geometries

- 2 special devices for screw testing up to screw sizes of M72 (Sincotec)

- Control of testing machines FlexTest 60 (MTS Systems)

Measuring equipment

- Highspeed digital camera incl. various accessories (Keyence)

- Digital microscope VHX 1000 incl. various accessories (Keyence)

- 2 x ARAMIS 3D 12M - System incl. various accessories (GOM)

- Roughness measuring device (Jenoptik)

- Welding laboratory: MSG welding machine with feed tractor, welding table and suction device

- Various high-precision mobile measuring and testing devices for the detection of strains, displacements, accelerations and temperatures

- Processing machines: lathe, milling machine, bench drilling machine, saws

- High temperature furnace (Nabertherm)

- Muffle furnaces (Nabatherm)

Further possibilities

The Institute of Steel Construction has also access to other experimental facilities of the faculty in the Testzentrum Tragstrukturen:

- Climate chamber with sea salt simulation

- Foundation test pit (14 m x 9 m x 10 m), 3D clamping field with various test cylinders, resonance testing machine 1MN

- Various special laboratories (Structural Health Monitoring (SHM) laboratory, soil mechanics laboratory, concrete laboratory, composite laboratory, workshop)